Solving the problem

As the function of the this mold slide or chute seems trivial at first glance, it becomes extremely valuable when you face problems like:

• Product gets damaged when ejected out of the machine;

• Product falls on the existing product made in previous cycle and damages itself or the part below;

• You installed metal slide / chute / toboggan and now you face loud banging every time the product is ejected;

• You installed metal slide / chute / toboggan and the product damages when it hits the hard surface;

• You covered the metal slide with cloth or silicone and you have found out, that now the product does not slide and the product is damaged when next product falls on it;

• You installed cardboard and you have found out that it does hold more than 1000 cycles;

• You installed PVC or Teflon slide or chute and you have found out that very soon the injection molded product makes the hole in the mold chute as the ejected product is falling always on the very same spot. Especially if you are using fiber glass reinforced products or you have sprues with sharp edges.

Do not worry, we have gone through the same problems.

It took us many testing, trial & error since we finally produced the right mold slide (or mold chute) that:

• Endures the falling of the plastic product on the same spot thousands of times;

• Enables the sliding of the product after its has been successfully caught;

• Enables easy installation on every possible machine;

• Endures the temperatures of the hot plastic product.

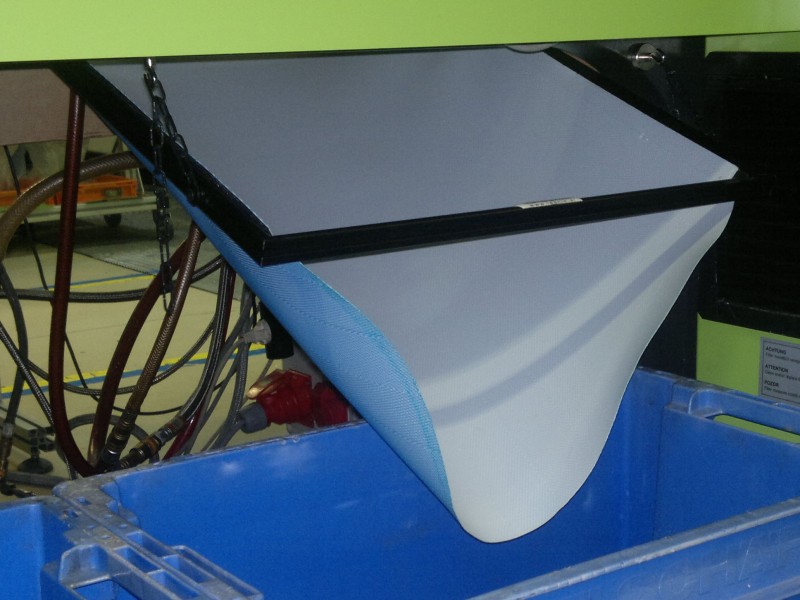

Only when we developed special multi layered machine slide, where the upper layer functions as a very easy gliding slide material and lower stronger layers function as the carrier of the collision force, we managed to solve the so called trivial problem…

And then we made another one, and anther one for the company nearby. .

..And since than in last few years we made more than 70 different sizes of machine slides

constantly improving the design and the features!

We found out, that we have a product – toboggan/chute/slide for injection molded products, that really solves the problem!

And that it is worth showing it to you.. It is very likely that you might find it very valuable as well!

Easy installation

Our machine slides are very easy to install on every kind of machine.

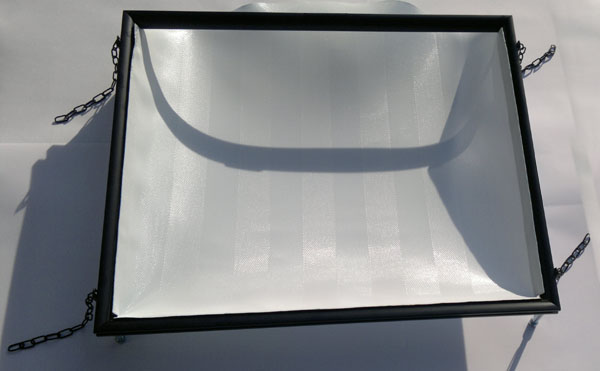

They come equipped with 4 strong special magnets on small chains that attach to every surface of the machine. They are so strong, that even installed on vertical surface of the machine, they do not slide down with time.

As we use hooks with the magnets, not the entire lenght of the holding chain needs to be used. You can easily use any other chain link, in case you find it more suitable for fixation to the magnet.

The frame of our chute has sliding nut, which makes the positioning of the magnet even easier!

With ease you may slide the chains along the side of the slide and find the best position for positioning on your machine.

Special fabric

It is the special multilayer fabric that makes our “product toboggan” so durable. On the top, the temperature resistant material is dense and “ironed” for nice gliding properties. There is no possibility of sprues or conical products to stick into the slide. In the lower layers the material is very strong to endure and dissipate the colliding energy of the product. The middle layers bind those layers and make sure that the material is still flexible and bends easily.

Strong magnets

Our slides / chutes can be fixed to any machine using our very strong rare earth magnets.

This magnets do not slide even if attached to vertical machine surface!

Many dimensions

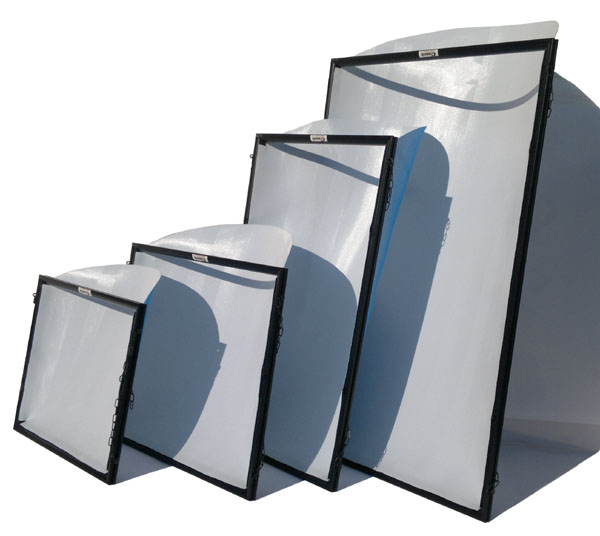

Every machine has its own design, which means different dimensions of the machine frame demands different slide sizes.

With more than 70 different sizes of the injection mold sliding chutes made, we are able to produce the standard sized slide for your machine.

Customization

Not all the machines are the same, also your needs may be different:

Some would like to have the slide longer, so it extends out of the machine, some would like to positon it along the axis of the machine, some perpendicular to the machine axis…

We listen to you needs and we are able to produce custom sized slides / chutes according to your given dimensions!

Additional information

Please use the “contact us” page in order to request the datasheet file

and for any additional information you may require.

We are happy to provide you answers regarding the features of the product.